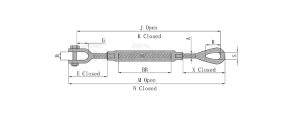

Feature:

| Size (in) |

Working Load Limit (lbs) |

Weight (lbs) |

Dimensions(in) | |||||||||||

| A | B | E Closed |

G | J Open |

K Closed |

M Open |

N Closed |

R | S | X Closed |

BB | |||

| 1/4*4 | 500 | 0.32 | 0.25 | 0.41 | 1.58 | 0.62 | 11.35 | 7.35 | 2.07 | 8.07 | 0.78 | 0.34 | 1.75 | 4.00 |

| 5/16*4 1/2 | 800 | 0.47 | 0.31 | 0.47 | 1.98 | 0.87 | 13.71 | 8.71 | 14.01 | 9.51 | 0.94 | 0.44 | 2.09 | 4.50 |

| 3/8*6 | 1200 | 0.76 | 0.38 | 0.50 | 2.12 | 0.87 | 16.81 | 10.81 | 17.77 | 11.77 | 1.12 | 0.53 | 2.52 | 6.00 |

| 1/2*6 | 2200 | 1.53 | 0.50 | 0.63 | 2.75 | 1.06 | 18.29 | 12.28 | 19.48 | 13.48 | 1.44 | 0.72 | 3.23 | 6.00 |

| 1/2*9 | 2200 | 1.71 | 0.50 | 0.63 | 2.75 | 1.06 | 24.29 | 15.29 | 25.48 | 16.48 | 1.44 | 0.72 | 3.23 | 9.00 |

| 1/2*12 | 2200 | 2.06 | 0.50 | 0.63 | 2.75 | 1.06 | 30.29 | 18.29 | 31.48 | 19.48 | 1.44 | 0.72 | 3.23 | 12.00 |

| 5/8*6 | 3500 | 2.35 | 0.63 | 0.75 | 3.50 | 1.31 | 19.74 | 13.74 | 21.28 | 15.28 | 1.75 | 0.88 | 3.90 | 6.00 |

| 5/8*9 | 3500 | 3.06 | 0.63 | 0.75 | 3.50 | 1.31 | 25.74 | 16.74 | 27.28 | 18.28 | 1.75 | 0.88 | 3.90 | 9.00 |

| 5/8*12 | 3500 | 3.78 | 0.63 | 0.75 | 3.50 | 1.31 | 31.74 | 19.74 | 33.28 | 21.28 | 1.75 | 0.88 | 3.90 | 12.00 |

| 3/4*6 | 5200 | 4.00 | 0.75 | 0.94 | 4.18 | 1.50 | 21.19 | 15.19 | 23.11 | 17.11 | 2.09 | 1.00 | 4.69 | 6.00 |

| 3/4*9 | 5200 | 4.75 | 0.75 | 0.94 | 4.18 | 1.50 | 27.19 | 18.19 | 29.11 | 20.11 | 2.09 | 1.00 | 4.69 | 9.00 |

| 3/4*12 | 5200 | 5.36 | 0.75 | 0.94 | 4.18 | 1.50 | 33.19 | 21.19 | 35.11 | 23.11 | 2.09 | 1.00 | 4.69 | 12.00 |

| 3/4*18 | 5200 | 7.00 | 0.75 | 0.94 | 4.18 | 1.50 | 45.19 | 27.19 | 47.11 | 29.11 | 2.09 | 1.00 | 4.69 | 18.00 |

| 7/8*12 | 7200 | 8.00 | 0.88 | 1.13 | 4.85 | 1.75 | 34.34 | 23.34 | 36.57 | 24.57 | 2.38 | 1.25 | 5.10 | 12.00 |

| 7/8*18 | 7200 | 9.75 | 0.88 | 1.13 | 4.85 | 1.75 | 46.34 | 28.34 | 48.57 | 30.57 | 2.38 | 1.25 | 5.10 | 18.00 |

| 1*6 | 10000 | 8.92 | 1.00 | 1.19 | 5.53 | 2.06 | 24.34 | 18.34 | 26.89 | 20.89 | 3.00 | 1.44 | 6.36 | 6.00 |

| 1*12 | 10000 | 11.20 | 1.00 | 1.19 | 5.53 | 2.06 | 36.34 | 24.34 | 38.89 | 26.89 | 3.00 | 1.44 | 6.36 | 12.00 |

| 1*18 | 10000 | 13.30 | 1.00 | 1.19 | 5.53 | 2.06 | 48.34 | 30.34 | 50.89 | 32.89 | 3.00 | 1.44 | 6.36 | 18.00 |

| 1*24 | 10000 | 17.00 | 1.00 | 1.19 | 5.53 | 2.06 | 60.34 | 36.34 | 62.89 | 38.89 | 3.00 | 1.44 | 6.36 | 24.00 |

| 1 1/4*12 | 15200 | 20.00 | 1.25 | 1.75 | 7.21 | 2.81 | 38.82 | 26.82 | 42.05 | 30.05 | 3.56 | 1.81 | 7.72 | 12.00 |

| 1 1/4*18 | 15200 | 24.18 | 1.25 | 1.75 | 7.21 | 2.81 | 50.82 | 32.82 | 54.05 | 36.05 | 3.56 | 1.81 | 7.72 | 18.00 |

| 1 1/4*24 | 15200 | 28.50 | 1.25 | 1.75 | 7.21 | 2.81 | 62.82 | 38.82 | 66.05 | 42.05 | 3.56 | 1.81 | 7.72 | 24.00 |

| 1 1/2*12 | 21400 | 28.99 | 1.50 | 2.06 | 7.88 | 2.81 | 40.50 | 28.50 | 44.25 | 32.25 | 4.06 | 2.12 | 8.62 | 12.00 |

| 1 1/2*18 | 21400 | 35.00 | 1.50 | 2.06 | 7.88 | 2.81 | 52.50 | 34.50 | 56.25 | 38.25 | 4.06 | 2.12 | 8.62 | 18.00 |

| 1 1/2*24 | 21400 | 39.18 | 1.50 | 2.06 | 7.88 | 2.81 | 64.50 | 40.50 | 68.25 | 44.25 | 4.06 | 2.12 | 8.62 | 24.00 |

| 1 3/4*18 | 28000 | 53.75 | 1.75 | 2.38 | 9.40 | 3.38 | 55.38 | 37.38 | 59.78 | 41.78 | 4.62 | 2.38 | 10.00 | 18.00 |

| 1 3/4*24 | 28000 | 60.68 | 1.75 | 2.38 | 9.40 | 3.38 | 67.38 | 43.38 | 71.78 | 47.78 | 4.62 | 2.38 | 10.00 | 24.00 |

| 2 * 24 | 37000 | 89.00 | 2.00 | 2.50 | 11.86 | 3.69 | 72.62 | 48.62 | 77.95 | 53.95 | 5.75 | 2.69 | 13.09 | 24.00 |

| 2 1/2 * 24 | 60000 | 150.00 | 2.50 | 2.88 | 13.56 | 4.44 | 75.80 | 51.80 | 82.40 | 58.40 | 6.50 | 3.12 | 13.78 | 24.00 |

| 2 3/4 * 24 | 75000 | 183.00 | 2.75 | 2.50 | 15.22 | 4.19 | 77.88 | 53.88 | 85.50 | 61.50 | 7.00 | 3.25 | 15.22 | 24.00 |

1.4 perfect forging lines – our main products include standard rigging products and customized products,the annual production capacity is 3000T.

2.Track the whole production process from raw materials to finished products and strictly control the process flow.

3.With an experienced R&D and design team of 5 people, we can make professional 3D modeling and product animation,provide you product and packaging customization.

4.Insisted on “customer-centric” business philosophy, and strive to provide customers with high quality, efficient and personalized service.

5.Strictly control quality of every batch product, inspecting and test before shipment.

|

Copyright © Qingdao Sail Rigging Co., Ltd. All rights reserved.