In the realm of rigging and engineering, standards are the backbone that ensures uniformity, quality, and safety. DIN 1478, a German Industrial Standard, specifically addresses the design, dimensions, and specifications for turnbuckles. This article aims to provide an in-depth understanding of DIN 1478, shedding light on its significance in the world of rigging and its role in promoting reliability and consistency.

1.Design and Dimensions:

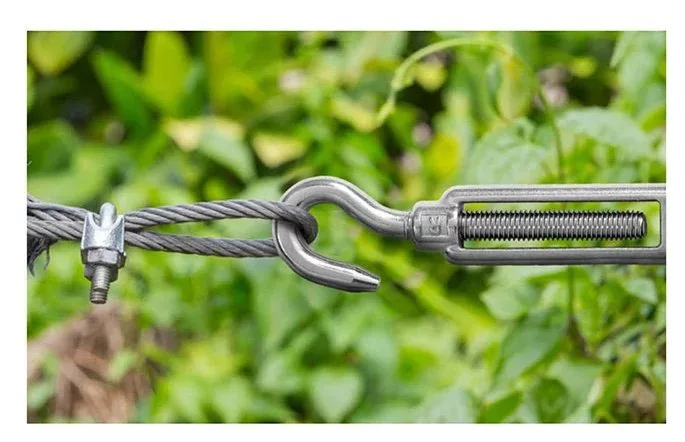

At the core of DIN 1478 is its meticulous detailing of the design and dimensions of turnbuckles. This includes specifications for the central body, threaded components, and overall geometry. By establishing precise parameters, the standard ensures that turnbuckles produced under DIN 1478 adhere to a consistent design.

2.Materials and Construction:

DIN 1478 often stipulates the acceptable materials for manufacturing turnbuckles. Whether it’s steel or stainless steel, the standard provides guidelines on the type and quality of materials to be used. This ensures that turnbuckles maintain the necessary strength and durability for their intended applications.

3.Thread Specifications:

Turnbuckles covered by DIN 1478 typically feature opposite-handed threads on the two components. This design facilitates simultaneous rotation for precise length adjustments. The standard outlines thread specifications, including pitch and diameter, contributing to the turnbuckle’s functionality and compatibility.

4.Load Ratings:

Critical for safe usage, DIN 1478 often includes information on load ratings or working load limits. Users can refer to these specifications to ensure that the turnbuckles are employed within their designated capacity, promoting safety and preventing overloading.

5.Testing and Quality Control:

To guarantee the reliability of turnbuckles, DIN 1478 incorporates requirements for testing and quality control during the manufacturing process. This ensures that each turnbuckle meets stringent criteria for performance and durability.

6.Marking and Identification:

The standard addresses how turnbuckles should be marked and identified. This includes details such as the manufacturer’s name, DIN standard number, and any other relevant information. Proper marking enhances traceability and assists users in verifying compliance.

7.Compliance and Certification:

Manufacturers producing turnbuckles in accordance with DIN 1478 must adhere to its specifications to achieve compliance. Users can look for DIN 1478 certification or compliance marks to ensure that the turnbuckles meet the established standards.

In a conclusion, DIN 1478 stands as a beacon of standardization in the world of turnbuckles, providing a framework that ensures consistency, safety, and quality. From design and materials to load ratings and testing procedures, the standard encapsulates essential guidelines for manufacturers and users alike. As with any standard, it is crucial to stay informed about updates or revisions to ensure that the latest specifications are followed. DIN 1478’s impact extends beyond its native Germany, influencing global practices in the production and utilization of turnbuckles for diverse rigging applications. If you want to know more about DIN1478 turnbuckles, feel free to contact Sail Rigging now.