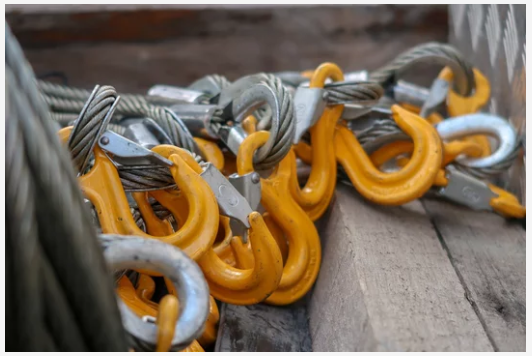

Lifting hooks play a crucial role in various industries, providing a reliable means of lifting and securing heavy loads. There’s different type of lifting hooks for your choose, such as US Type Eye Hook S320, Swivel Hook s322, Clevis Slip Hook With Latch, Clevis Slip Hook H331/A331, Eye Slip Hook With Latch, Eye Slip Hook H324/A324, Eye Grab Hook H323/A323, Clevis Grab Hook H330/A330, Open Hook, Tow Hook, J Hook, Welding Hook, Forest Hook For Logging, ect. Among the numerous types available, G43, G70, G80 lifting hooks are widely used due to their specific characteristics and advantages. In this article, we will explore the differences between these types of lifting hooks, their respective advantages, and common applications in different industries.

G43 Lifting Hooks

G43 lifting hooks are made from high-strength, heat-treated carbon steel. They are known for their excellent resistance to wear and corrosion. These hooks are commonly used in applications that require medium to heavy lifting, such as construction, marine, and transportation.

G70 Lifting Hooks

G70 lifting hooks or sling hooks are an upgrade from G43, offering higher strength and load-carrying capacity. These hooks are often utilized in situations where heavier loads need to be lifted with enhanced safety measures.

G80 Lifting Hooks

G80 lifting hooks are designed for even more demanding lifting tasks, providing superior strength and durability. These hooks are commonly used in industries where safety and reliability are paramount.

| Grade | Material | Advantages | Applications |

|---|---|---|---|

| Grade 43 | Made from high-strength, heat-treated carbon steel. | Good strength-to-weight ratio. | Construction sites for lifting and moving heavy materials. |

| Offers a balance of strength and flexibility. | Durable and resistant to environmental factors. | Marine industry for hoisting and securing loads on ships. | |

| - | Suitable for general lifting applications. | Transportation for securing cargo during transit. | |

| Grade 70 | Contains a higher percentage of carbon and manganese compared to G43. | Higher strength compared to G43 hooks. | Heavy-duty construction projects. |

| Provides increased strength and load-carrying capacity. | Ideal for heavy-duty lifting operations. | Transportation of oversized and heavy cargo. | |

| - | Excellent resistance to abrasion and wear. | Logging operations for lifting and moving large timber. | |

| Grade 80 | Further refinement in material composition, featuring alloy steel. | Exceptional strength and durability. | Oil and gas industry for lifting and transporting heavy equipment. |

| Offers superior strength, durability, and resistance to wear. | Resistant to deformation under heavy loads. | Mining operations for hoisting ore and machinery. | |

| - | Suitable for critical lifting applications. | Rigging applications where precision and reliability are essential. |

In conclusion, G43, G70 and G80 lifting hooks cater to a wide range of lifting requirements, each offering unique advantages suited to specific applications. The choice of the appropriate lifting hook depends on the nature of the lifting task, the weight of the load, and the environmental conditions. Understanding these differences allows industries to make informed decisions to ensure the safety and efficiency of their lifting operations. If you want to know more about the grade of lifting and sling hooks, please contact Sail Rigging right now.