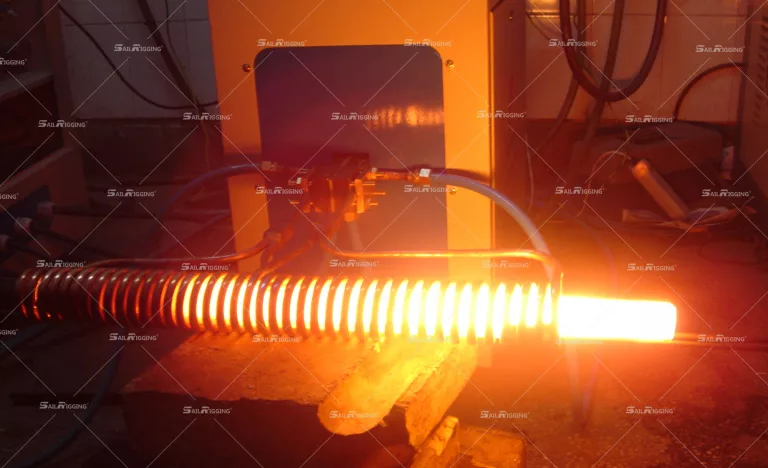

Today we are talking about the breaking strength of turnbuckles, the minimum breaking strength (M.B.S) is 4-6 times. The difference is if heat treatment or not. If turnbuckles after drop forged and heat treatment is 6 times, drop forged but no heat treatment is 4 times.Hot heat treatment is very important manufacturing process, involves heating the metal to a specific temperature and then cooling it at a controlled rate to increase the material’s strength, durability and resistance to wear and tear.

Do You Know What’s the advantage of Hot Heat Treatment Of Turnbuckles?

- Enhanced Strength And Durability

Heat treatment significantly increases the strength of the turnbuckle, making it capable of withstanding high loads and stresses without deforming or breaking. The enhanced durability ensures that the turnbuckle remains functional even in demanding environments, such as construction sites, marine applications, and heavy industrial settings.

- Corrosion Resistance

Hot heat-treated turnbuckles are often made from materials like stainless steel or galvanized steel, which are further enhanced by the heat treatment process. This results in increased resistance to rust and corrosion, especially in harsh environments like marine or outdoor applications. The added protection against corrosion extends the life of the turnbuckle, reducing the need for frequent replacements and maintenance.

- Improved Safety

Turnbuckles used in lifting, rigging, and tensioning operations must handle immense forces. A heat-treated turnbuckle is less prone to failure under heavy loads, ensuring a safer operation. With the increased strength and resilience that comes from heat treatment, hot heat turnbuckles are a safer choice for critical applications, reducing the risk of accidents or equipment failure.

- Precision and Reliability

The heat treatment process ensures the turnbuckle maintains its shape and load-bearing capacity over time. This makes it more reliable in situations where precise tension control is necessary, such as when securing loads or adjusting the tension of cables and ropes. Turnbuckles with hot heat treatment maintain their integrity even under fluctuating loads, providing consistent performance in challenging conditions.

- Versatility Across Applications

Hot heat turnbuckles can be used across a wide range of industries, from construction and transportation to marine and industrial sectors. Their enhanced strength and durability make them ideal for tasks that require secure connections and tension adjustments.They are also available in various sizes and configurations, making it easy to choose the right type of turnbuckle for specific tasks.

In a conclusion, hot heat turnbuckles are an essential part of any rigging system, offering enhanced strength, durability, and resistance to corrosion. Whether you’re working in construction, marine, or industrial environments, the added benefits of hot heat treatment can improve the performance, safety, and longevity of your rigging hardware. Choosing the right turnbuckle for your needs will help ensure that your equipment performs reliably, even under the most demanding conditions. For more information on our range of hot heat turnbuckles and other rigging hardware, visit our website or contact Sail Rigging.