A Comprehensive Guide to the Different Types of Shackles

What is a shackle?

A shackle is a U-shaped or clamp-shaped connecting ring that is fixed at the opening with a U-shaped pin or bolt. It is mainly used to connect and fix various wire ropes, chains, etc. It is widely used in industrial fields such as lifting, hoisting, traction, transportation, and fixing.

Table of Contents

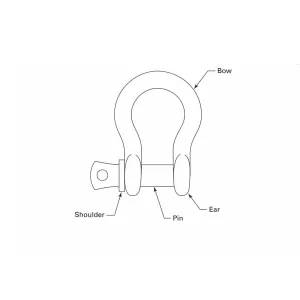

How many parts does a shackle consist of?

Bow – the curved part of the shackle body opposite the pin – commonly called a ring buckle, body, D-shaped or bowl-shaped

Ear – the part of the shackle body that supports the shackle pin

Pin – a steel bolt used to span the two shackle ears

Shoulder – the part where the pin contacts the ear when the pin is fully tightened or engaged

How many types of shackles are there?

By shape: dee and bow shackles

Dee shackles, also known as chain shackles, are narrow shackles shaped like chain links, usually with pins or threaded pin buckles, and are common in large industrial and marine applications. They have a U-shaped ring with a pin at one end, which can easily withstand strong load forces and have the flexibility to move. Chain shackles or eyelet shackles have oval links that are wider than normal links. This wider gap makes it easier to insert items into or remove items from the shackle.

Bow shackle, also known as the anchor shackle, is an “O” shaped metal link that is closed by a bolt. It is the most commonly used shackle in rigging. They have a wide range of sizes and capacities and are the most commonly used shackles in rigging. Anchor shackles usually have a larger bow shape and have a higher load rating. This gives them a larger force-bearing area and a longer service life.

By standards: American, European, Australian, Japanese shackles

American shackles are forged and heat-treated with high-quality carbon structural steel or alloy structural steel. They are small in size and high in strength; the test load is 2 times the ultimate working load, and the breaking load is 4-6 times the ultimate working load. The American standard shackles are 1/4-4-1/2, with more than 20 specifications from 2 tons to 200 tons. The American standard shackles are divided into four forms: 210, 2150, 209, and 2130.

European shackles are made of high-quality low-carbon steel for free forging, and the surface is electrogalvanized. They are relatively light, but their tensile strength and corrosion resistance are poor. European standard shackles are usually in metric units, ranging from 5 mm to 50 mm. The specifications of European standard shackles usually include length, width and height. European standard shackles are divided into European large bow shackles and European large D shackles.

Australian shackles are forged with high-quality high-carbon steel or alloy structural steel and heat treated. They follow the Australian standard AS2741. The shackle grades are divided into M and S grades. The breaking load is 4-6 times the ultimate working load. It is usually in metric units, ranging from 6mm to 102mm. It is divided into straight and bow shackles. The “bow” design provides greater angular displacement.

Japanese shackles, shackles that meet the Japanese Industrial Standard (JIS) B2801-1977 standard, are made of high-quality low-carbon steel for free forging, and the surface is electro-galvanized. The specifications range from 5mm to 75mm. Japanese shackles are divided into Japanese D-type shackles and Japanese gearless shackles, and the working tension ranges from 0.09t to 20t.

By pin: srew pin shackles and bolt shackles, round pin shackles

The design of screw pin shackles is similar to that of anchor shackles. However, they have a threaded pin that engages with the nut to prevent the shackle from slipping out when loaded. Unlike typical pins, they provide the security of spiral fasteners and eliminate any possibility of accidental movement of the pin. They are often used in heavier lifting applications and create a secure connection between chains, slings and other rigging components.

Bolt shackles are very similar to spiral pin shackles. However, instead of a threaded pin, they have an oversized bolt with a drilled hole for a temporary locking mechanism. This shackle type is popular in the industry for its high load capacity and versatility in multiple rigging and lifting applications. It is often used in harsh environments where breakage or fatigue may occur. The bolt design provides additional security by allowing for a secure and easy connection between objects.

Round Pin Shackles feature their unique round pins and are designed to handle heavy loads. They are one-piece plated and forged, making them durable and resilient in high temperature applications. Since all the load is borne directly by the pin, these shackles have an unmatched strength-to-weight ratio. They are suitable for use with either manila rope or wire rope. These shackles have good corrosion resistance and can withstand long-term exposure to harsh weather conditions.

By material, hot dip galvanized, electro galvanized, stainless steel shackles.

Hot dip galvanized shackles are the most basic, versatile and economical type of shackle. They are used for most general purpose applications, both indoors and outdoors. Although moderately resistant to corrosion, many find it easy to inspect and maintain.

Electro-galvanized shackles, also known as cold-dip galvanized shackles, are more economical than hot-dip galvanizing, have a smoother surface, and provide adequate corrosion resistance for indoor use and mild outdoor environments.

Stainless steel shackles are more corrosion resistant, ideal for marine applications. Our stainless steel shackles are made from 304 and 316 stainless steel and are considered “marine grade”. 316 marine grade stainless steel contains molybdenum which makes it resistant to seawater mist or spray and therefore particularly useful in extreme conditions or in wet or high chloride environments. 316 stainless steel type D shackle equipment is ideal for sailboat and yacht rigging purposes.

Application Of Shackles

Shackles can be used in many different rigging and load securing applications, as well as where different types of lifting slings, chains or ropes are connected. They are widely used in various industries such as power, metallurgy, petroleum, machinery, railways, chemicals, ports, mining, construction, etc.

What should you avoid when using shackles?

- Do not exceed the specified safe load.

- Make sure the shackle has no defects, no cracks, sharp edges, excessive burns or other deformations.

- Do not replace the shackle pin with a bolt or unidentified pin, the load will bend the bolt.

- Do not replace the shackle pin with a bolt

- Do not pull the shackle at an angle. The legs will open. Wrap the pin with a washer to center the shackle.

- Wrap the pin with a washer to center the shackle

- Do not use a screw pin shackle or install the pin in a position that contacts the moving part if the pin can roll and loosen. If the load moves, the sling will loosen the shackle pin.

- Do not use a round pin shackle that is only restrained by a cotter pin for overhead lifting.

- Do not use a screw pin shackle if the pin can roll and loosen

- Do not use a shackle with a bent pin or deformed body.

- Do not force, hammer or wedge the shackle.

- When using a multi-leg sling, do not exceed an angle of 120 degrees.

If you want more information about shackle types, you can contact us by email at manager@qdsailrigging.com. We are happy to share more useful information with you.