How To Measure Shackles?

The shackle is the standard and most cost-effective way to connect the anchor to the chain. The shackle is the weakest link in the system, so choosing the right size shackle is crucial. Important parameters of shackles are shape, material, pin type and working load limit.

Table of Contents

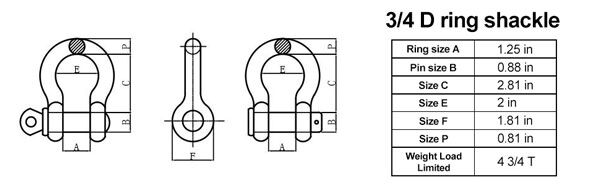

Shackle Sizes

When measuring the length of a rigging shackle, it is important to note that the measurement provided is based on the diameter of the shackle body, not the diameter of the shackle pin. It is important to note that in the American die forged shackles and international shackles, the material diameter of the body and the material diameter of the pin are inconsistent, and the material diameter of the pin is larger than the material diameter of the body. In the free forged shackles, Japanese D-type shackles, European large D shackles and European large bow shackles, the material diameter of the shackle body and the material diameter of the pin are consistent. The different shackle, the size are different. You could view this to get your interested shackles.

The following figure provides a guide on how to prepare to measure the length of the shackle.

Steps To Measure Shackles

Shackles come in various sizes and configurations, and understanding their critical dimensions is crucial for selecting the right shackle for your specific application.If the size of the shackle we choose is unsuitable, it will affect the connection and use. Now let’s look at some of the critical dimensions that affect the link. The following are some of the critical dimensions to consider when measuring shackles:

- Pin Diameter (Dp):The pin diameter is one of the most critical dimensions of a shackle. It determines the strength and load capacity of the shackle. Measure it accurately using a caliper or ruler, taking the widest part of the pin into account.

- Inside Width (W):The inside width is the distance between the inner edges of the shackle legs, excluding the pin. This dimension is essential for determining compatibility with other rigging equipment, such as hooks, slings, or cables.

- Bow Diameter (for Bow Shackles) (Db):In the case of bow shackles, the bow diameter is the measurement across the widest part of the bow or the rounded portion. It plays a role in determining the space available for attachment and can affect the shackle’s capacity to accommodate oversized loads.

- Body Width (for D-Shackles) (Dw):D-Shackles have a straight body width measurement, which is the distance across the widest part of the shackle body. This measurement is important for understanding the space available for connecting hardware.

- Throat Opening (T):The throat opening is the space between the inside edges of the shackle legs. It is a critical dimension when selecting shackles for applications where they need to be connected to other components or where items are threaded through the shackle.

- Eye Diameter (for Anchor Shackles):In anchor shackles, the eye diameter is the distance across the rounded eye at the top of the shackle. This dimension is vital when the shackle is used for connecting to anchor points, hooks, or other rigging hardware.

- Working Load Limit (WLL):The Working Load Limit (WLL) is not a physical dimension but a critical specification that indicates the maximum load the shackle can safely handle. It is typically marked on the shackle and should never be exceeded. The WLL is influenced by the shackle’s material, size, and design.

- Material and Grade:While not a physical dimension, knowing the material and grade of the shackle is essential. Shackles can be made of materials such as stainless steel, alloy steel, or carbon steel. The grade indicates the shackle’s strength and durability. Higher-grade shackles are suitable for heavy-duty applications.

- Weight:The weight of the shackle can be significant, especially in applications where weight restrictions apply. Measuring the weight of the shackle provides valuable information for transport and handling.

- Shackle Type:Identify whether you are dealing with a bow shackle or a D-shackle, as each type has specific applications and dimensions.

Always consult the manufacturer’s specifications and guidelines to ensure you have accurate information about the critical dimensions of the shackle you are using. Additionally, regular inspection and maintenance of shackles are vital to ensure safety and prolong their lifespan.

Important Rules of Using Shackles

- Replace shackle pins with bolts or unidentified pins. Loads can bend bolts.

- Allow shackles to pull at an angle. Legs can splay. Wrap pins with washers to center shackles.

- If pins can roll and loosen, use threaded pin shackles or round pins that contact moving parts. If the load moves, the sling can loosen the shackle pin.

- Only use round pin shackles secured with cotter pins for overhead lifting.

- Use shackles with bent pins or deformed bodies.

- Secure shackles in place with force, hammering, or wedges.

- When using multi-leg slings, the angle should not exceed 120 degrees.

FAQs on Shackle Measurement

- How do I measure the size of a shackle?

To measure the size of a shackle, use a tape measure or caliper to measure its diameter, width, and inside length.

2. Do shackles have standard sizes?

Yes, shackles have standard sizes, and the sizes of shackles of different standards are different. Please refer to the sizes of different shackles. But we can also customize the size according to specific requirements.

3.Can I measure a shackle in use?

For safety reasons, it is not recommended to measure a shackle in use. Please remove the shackle from the equipment before measuring.

4.How do I measure the diameter of the shackle pin?

Use a caliper or micrometer to accurately measure the diameter of the shackle pin.

5. Should I measure a shackle with or without a pin?

Measure the shackle without a pin to get the accurate size for selection and compatibility testing.

6. Are there any specific guidelines for measuring stainless steel shackles?

Although the measurement methods are the same, factors such as corrosion resistance and material strength need to be considered when selecting a stainless steel shackle.

7. What size is a 1 ton shackle?

Size: 3/8 in,Weight: 0.31 lbs. Sail Rigging G209 Bow Shackles are designed with a 6:1 design factor or 4:1 design factor. The difference is heat treatment.

8. What size is an 8.5 ton shackle?

Size:1 in, weight 5.32lbs, Sail Rigging G209 Carbon Steel bow shackle could reach 8.5t WLL, the ultimate load is 4-6 times of the WLL.

9. How do you calculate safe working load?

Safe working load, also called working load limit, it could be calculated by tensile tester. Sail Rigging could do tensile test by ourself, also accept Third-party testing company.

Conclusion

Measuring the size of the shackle is crucial to choosing the right shackle. If you want to know more information of shackles, feel free to contact Sail Rigging.