US Type Drop Forged Jaw And Eye Turnbuckles are made from high tensile carbon steel and hot dip galvanized. The ultimate load is 5 times the working load limit. They features jaw and eye on two ends to allow rotating the reversed thread into the open frame turnbuckle body to tighten or loosen cables, ropes or tie rods. US Type Drop Forged Jaw and Eye Turnbuckles meets or exceeds the performance requirements of ASTM F1145, ideal for construction, marine and industrial applications.

Feature:

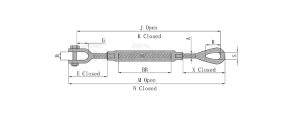

| Size (in) |

Working Load Limit (lbs) |

Weight (lbs) |

Dimensions(in) | |||||||||||

| A | B | E Closed |

G | J Open |

K Closed |

M Open |

N Closed |

R | S | X Closed |

BB | |||

| 1/4*4 | 500 | 0.32 | 0.25 | 0.41 | 1.58 | 0.62 | 11.35 | 7.35 | 2.07 | 8.07 | 0.78 | 0.34 | 1.75 | 4.00 |

| 5/16*4 1/2 | 800 | 0.47 | 0.31 | 0.47 | 1.98 | 0.87 | 13.71 | 8.71 | 14.01 | 9.51 | 0.94 | 0.44 | 2.09 | 4.50 |

| 3/8*6 | 1200 | 0.76 | 0.38 | 0.50 | 2.12 | 0.87 | 16.81 | 10.81 | 17.77 | 11.77 | 1.12 | 0.53 | 2.52 | 6.00 |

| 1/2*6 | 2200 | 1.53 | 0.50 | 0.63 | 2.75 | 1.06 | 18.29 | 12.28 | 19.48 | 13.48 | 1.44 | 0.72 | 3.23 | 6.00 |

| 1/2*9 | 2200 | 1.71 | 0.50 | 0.63 | 2.75 | 1.06 | 24.29 | 15.29 | 25.48 | 16.48 | 1.44 | 0.72 | 3.23 | 9.00 |

| 1/2*12 | 2200 | 2.06 | 0.50 | 0.63 | 2.75 | 1.06 | 30.29 | 18.29 | 31.48 | 19.48 | 1.44 | 0.72 | 3.23 | 12.00 |

| 5/8*6 | 3500 | 2.35 | 0.63 | 0.75 | 3.50 | 1.31 | 19.74 | 13.74 | 21.28 | 15.28 | 1.75 | 0.88 | 3.90 | 6.00 |

| 5/8*9 | 3500 | 3.06 | 0.63 | 0.75 | 3.50 | 1.31 | 25.74 | 16.74 | 27.28 | 18.28 | 1.75 | 0.88 | 3.90 | 9.00 |

| 5/8*12 | 3500 | 3.78 | 0.63 | 0.75 | 3.50 | 1.31 | 31.74 | 19.74 | 33.28 | 21.28 | 1.75 | 0.88 | 3.90 | 12.00 |

| 3/4*6 | 5200 | 4.00 | 0.75 | 0.94 | 4.18 | 1.50 | 21.19 | 15.19 | 23.11 | 17.11 | 2.09 | 1.00 | 4.69 | 6.00 |

| 3/4*9 | 5200 | 4.75 | 0.75 | 0.94 | 4.18 | 1.50 | 27.19 | 18.19 | 29.11 | 20.11 | 2.09 | 1.00 | 4.69 | 9.00 |

| 3/4*12 | 5200 | 5.36 | 0.75 | 0.94 | 4.18 | 1.50 | 33.19 | 21.19 | 35.11 | 23.11 | 2.09 | 1.00 | 4.69 | 12.00 |

| 3/4*18 | 5200 | 7.00 | 0.75 | 0.94 | 4.18 | 1.50 | 45.19 | 27.19 | 47.11 | 29.11 | 2.09 | 1.00 | 4.69 | 18.00 |

| 7/8*12 | 7200 | 8.00 | 0.88 | 1.13 | 4.85 | 1.75 | 34.34 | 23.34 | 36.57 | 24.57 | 2.38 | 1.25 | 5.10 | 12.00 |

| 7/8*18 | 7200 | 9.75 | 0.88 | 1.13 | 4.85 | 1.75 | 46.34 | 28.34 | 48.57 | 30.57 | 2.38 | 1.25 | 5.10 | 18.00 |

| 1*6 | 10000 | 8.92 | 1.00 | 1.19 | 5.53 | 2.06 | 24.34 | 18.34 | 26.89 | 20.89 | 3.00 | 1.44 | 6.36 | 6.00 |

| 1*12 | 10000 | 11.20 | 1.00 | 1.19 | 5.53 | 2.06 | 36.34 | 24.34 | 38.89 | 26.89 | 3.00 | 1.44 | 6.36 | 12.00 |

| 1*18 | 10000 | 13.30 | 1.00 | 1.19 | 5.53 | 2.06 | 48.34 | 30.34 | 50.89 | 32.89 | 3.00 | 1.44 | 6.36 | 18.00 |

| 1*24 | 10000 | 17.00 | 1.00 | 1.19 | 5.53 | 2.06 | 60.34 | 36.34 | 62.89 | 38.89 | 3.00 | 1.44 | 6.36 | 24.00 |

| 1 1/4*12 | 15200 | 20.00 | 1.25 | 1.75 | 7.21 | 2.81 | 38.82 | 26.82 | 42.05 | 30.05 | 3.56 | 1.81 | 7.72 | 12.00 |

| 1 1/4*18 | 15200 | 24.18 | 1.25 | 1.75 | 7.21 | 2.81 | 50.82 | 32.82 | 54.05 | 36.05 | 3.56 | 1.81 | 7.72 | 18.00 |

| 1 1/4*24 | 15200 | 28.50 | 1.25 | 1.75 | 7.21 | 2.81 | 62.82 | 38.82 | 66.05 | 42.05 | 3.56 | 1.81 | 7.72 | 24.00 |

| 1 1/2*12 | 21400 | 28.99 | 1.50 | 2.06 | 7.88 | 2.81 | 40.50 | 28.50 | 44.25 | 32.25 | 4.06 | 2.12 | 8.62 | 12.00 |

| 1 1/2*18 | 21400 | 35.00 | 1.50 | 2.06 | 7.88 | 2.81 | 52.50 | 34.50 | 56.25 | 38.25 | 4.06 | 2.12 | 8.62 | 18.00 |

| 1 1/2*24 | 21400 | 39.18 | 1.50 | 2.06 | 7.88 | 2.81 | 64.50 | 40.50 | 68.25 | 44.25 | 4.06 | 2.12 | 8.62 | 24.00 |

| 1 3/4*18 | 28000 | 53.75 | 1.75 | 2.38 | 9.40 | 3.38 | 55.38 | 37.38 | 59.78 | 41.78 | 4.62 | 2.38 | 10.00 | 18.00 |

| 1 3/4*24 | 28000 | 60.68 | 1.75 | 2.38 | 9.40 | 3.38 | 67.38 | 43.38 | 71.78 | 47.78 | 4.62 | 2.38 | 10.00 | 24.00 |

| 2 * 24 | 37000 | 89.00 | 2.00 | 2.50 | 11.86 | 3.69 | 72.62 | 48.62 | 77.95 | 53.95 | 5.75 | 2.69 | 13.09 | 24.00 |

| 2 1/2 * 24 | 60000 | 150.00 | 2.50 | 2.88 | 13.56 | 4.44 | 75.80 | 51.80 | 82.40 | 58.40 | 6.50 | 3.12 | 13.78 | 24.00 |

| 2 3/4 * 24 | 75000 | 183.00 | 2.75 | 2.50 | 15.22 | 4.19 | 77.88 | 53.88 | 85.50 | 61.50 | 7.00 | 3.25 | 15.22 | 24.00 |

1.4 perfect forging lines – our main products include standard rigging products and customized products,the annual production capacity is 3000T.

2.Track the whole production process from raw materials to finished products and strictly control the process flow.

3.With an experienced R&D and design team of 5 people, we can make professional 3D modeling and product animation,provide you product and packaging customization.

4.Insisted on “customer-centric” business philosophy, and strive to provide customers with high quality, efficient and personalized service.

5.Strictly control quality of every batch product, inspecting and test before shipment.

|

Copyright © Qingdao Sail Rigging Co., Ltd. All rights reserved.