Turnbuckle Rod Assemblies In Architecture

Turnbuckle rod assemblies play an essential role in architectural design and construction. These versatile systems are primarily used to provide precise tensioning in various building components, ensuring the integrity of key structural elements. Whether for cross-bracing, canopies, or suspension systems, turnbuckle rod assemblies are indispensable in modern architecture. Today we will explore the significance of turnbuckle […]

What Are Wire Rope Fittings?

Wire rope fittings are essential components used in conjunction with wire ropes to enhance their functionality, ensure secure connections, and provide reliable performance in lifting, securing, and load-handling applications. These fittings serve as terminations or attachment points, enabling wire ropes to connect with other rigging hardware or structures. Wire rope fittings come in various shapes, […]

What Are Tie Rod Assemblies?

Tie rod assemblies play a critical role in various construction, architectural, and industrial applications. Consisting primarily of a threaded rod and a turnbuckle, tie rod assemblies provide essential support and stabilization for structures that require tensioning. Available in different materials and surface finishes, tie rod assemblies are customizable to suit specific project needs, offering versatility […]

Turnbuckles For Lashing System

When transporting goods across oceans, proper securing of containers is crucial for maintaining ship stability and ensuring the safety of the cargo. As a ship travels through turbulent waters, the risk of containers shifting or tipping over increases dramatically. In these situation, turnbuckles play a key role in keeping the containers safely secured during the journey. […]

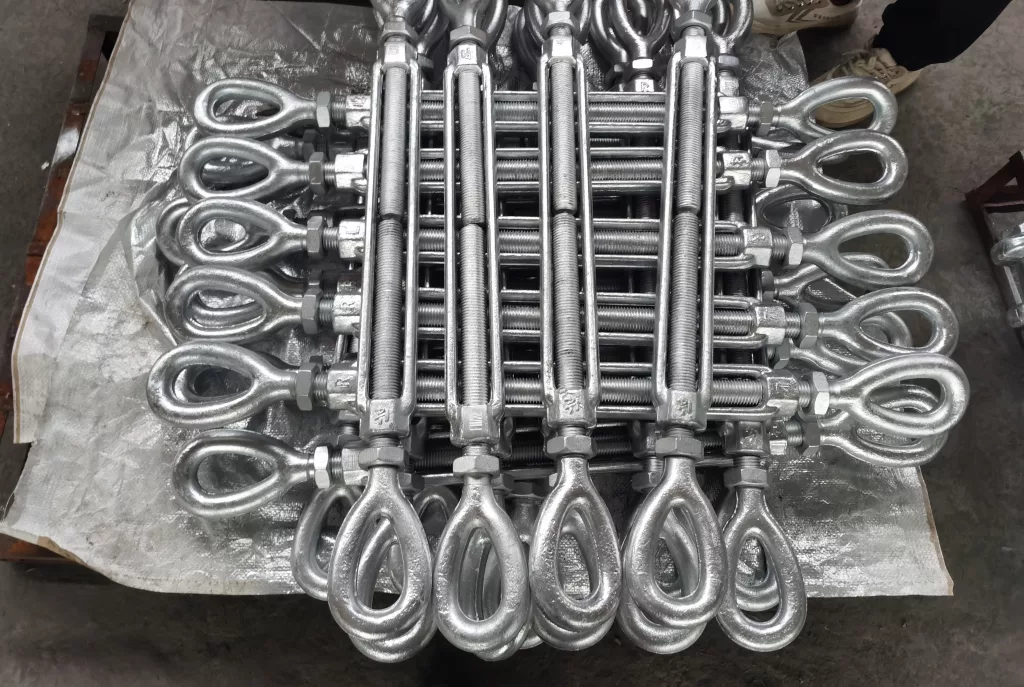

What’s US Type Drop Forged Turnbuckles?

Today we are talking about US Type Drop Forged Turnbuckles. US Type Drop Forged Turnbuckles are rigging devices specifically designed and manufactured to meet the rigorous safety and performance standards set by organizations like the ASME (American Society of Mechanical Engineers) and ASTM (American Society for Testing and Materials). These standards ensure that the turnbuckles […]

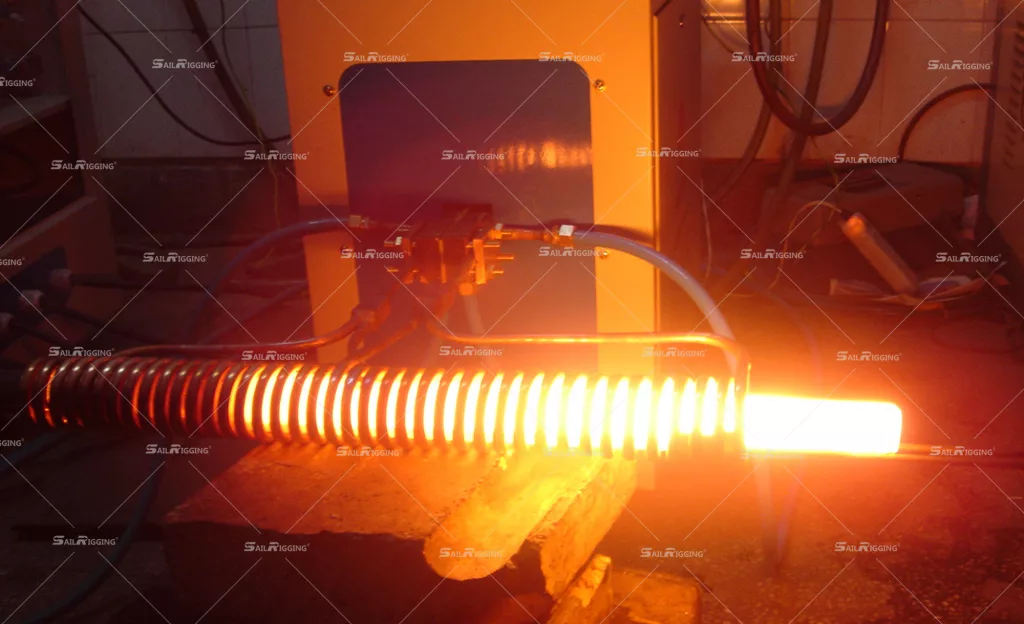

What’s The Advantage Of Heat Treatment Turnbuckles?

Today we are talking about the breaking strength of turnbuckles, the minimum breaking strength (M.B.S) is 4-6 times. The difference is if heat treatment or not. If turnbuckles after drop forged and heat treatment is 6 times, drop forged but no heat treatment is 4 times.Hot heat treatment is very important manufacturing process, involves heating […]

Turnbuckles in Sliding Gates

For over 15 years, Qingdao Sail Rigging Co., Ltd are focusing on supplying top-quality rigging hardware, specializing in turnbuckles. Turnbuckles are indispensable components in various applications, and one of their notable uses is in sliding gates. This article delves into the critical role turnbuckles play in the functionality and stability of sliding gates, ensuring they […]

3 Parts Of A Turnbuckle

Turnbuckles, also known as rigging screws or bottle screws, are crucial tools used to adjust the tension and length of ropes, cables, and other tensioning systems in various industries. They are widely utilized in construction, marine applications, and theater rigging due to their simplicity and effectiveness. There’re three main parts of a turnbuckle, the central […]

How To Test Turnbuckles?

Turnbuckles are essential components in various industries, providing adjustable tension in structures and systems. Proper testing is crucial to ensure their reliability and safety. This article presents a comprehensive guide to testing turnbuckles, covering visual inspection, dimension measurement, tensile testing, and zinc layer thickness assessment. Visual inspection This is the initial step in assessing […]

How to Conduct Magnetic Defect Test?

Magnetic defect testing stands as a cornerstone in quality assurance protocols, offering a reliable means of detecting flaws in ferromagnetic materials. By leveraging magnetic properties, this non-destructive testing method ensures structural integrity, regulatory compliance, and operational efficiency across diverse industries. Usually self color rigging hardware need to do magnetic defect testing, such as shackle, turnbuckle, […]