When it comes to securing heavy loads, choosing the right type of chain binder is critical for ensuring safety, efficiency, and compliance with industry standards. With various types of chain binders available, it’s essential to understand their features, advantages, and best-use scenarios. In this article, we’ll explore the main types of chain binders—lever binders and ratchet binders—and help you determine which one is best suited for your needs.

What Are Chain Binders?

Chain binders, also known as load binders, are devices used to tighten and secure chains around loads during transport. They are crucial for preventing cargo from shifting or falling during transit, particularly in industries like construction, agriculture, and logistics.

The two primary types of chain binders are: lever Load Binders and ratchet Load Binders

Each type offers unique features and benefits, making them suitable for different applications.

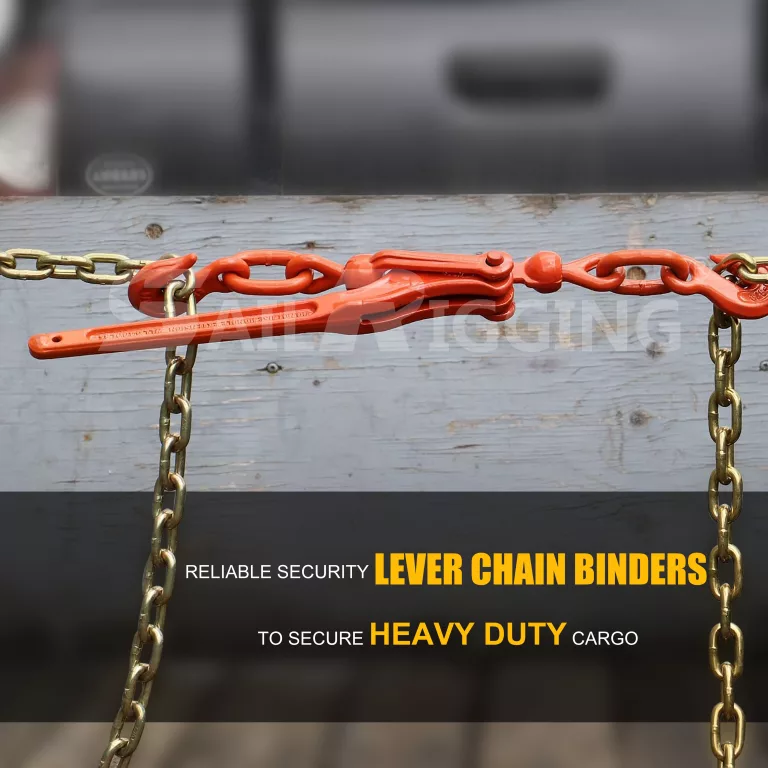

- Lever Load Binders

A lever load binder, also known as a snap binder, uses a lever to apply tension to the chain. The lever load binder provides mechanical advantage, making it easier to tighten the chain manually.It is used to increase the force applied to a tie-down. The lever is hinged and takes up the slack by pulling on one end of the tension hook and will lock itself after a 180-degree rotation of the lever around the hinge.

Advantages

- Quick and Simple Operation: The lever action allows for fast tightening and loosening, easy installation.

- Lightweight and Compact: Ideal for portability and field use.

- Cost-Effective: Lever binders are often more affordable than ratchet binders.

2.Ratchet Load Binders

A ratchet load binder uses a ratcheting mechanism to tighten chains gradually. This design allows for precise tensioning without sudden movements. When using a ratchet binder, the lever and screw work together and increase the force manually applied to the tie-down assembly. The result is that it takes much less pulling force on the handle to apply tension than you would need with a lever binder.

Advantages

- Safe and Controlled Operation: The ratcheting mechanism provides better control, minimizing safety risks. The take-up distance of a ratchet binder is typically eight to ten inches- twice that of a lever binder. It is more safer process and under control.

- High Tension Capability: Ideal for heavy-duty applications requiring significant chain tension.

- Ease of Use: Less physical strength is needed compared to lever binders. When using a ratchet binder, the lever and screw work together and increase the force manually applied to the tie-down assembly. it takes much less pulling force on the handle to apply tension than you would need with a lever binder.

Key Factors to Consider When Choosing a Chain Binder

When deciding which type of chain binder to use, consider the following factors:

- Load Weight and Size

- For light to medium loads, lever binders are often sufficient.

- For heavy or oversized loads, ratchet binders provide better control and safety.

2. Frequency of Use

- Lever binders are ideal for infrequent or short-term use.

- Ratchet binders are better suited for regular, long-term applications.

3. Safety Requirements

- If safety is a top priority, choose ratchet binders due to their controlled operation.

- Ensure compliance with industry standards such as ASTM, OSHA, or DOT regulations.

4. Operator Experience

- Experienced operators may prefer lever binders for their simplicity and speed.

- Less experienced users may find ratchet binders easier and safer to handle.

5. Budget Constraints

- Lever binders are more budget-friendly and cost-effective for occasional use.

- Ratchet binders, while pricier, offer long-term durability and safety benefits.

Applications of Chain Binders

Both lever and ratchet binders are used across various industries, including:

- Construction: Securing heavy machinery and equipment on flatbed trailers.

- Agriculture: Tying down tractors, hay bales, and other farm equipment.

- Logistics: Ensuring the stability of shipping containers and freight.

- Forestry: Transporting timber and logs.

- Personal Use: Hauling boats, ATVs, and other recreational vehicles.

In a conclusion, both lever binders and ratchet binders work in a similar way, ideal for tightening and securing chains around loads during transport. If speed and affordability are your priorities, lever binders may be the best option. However, if safety, control, and heavy-duty capability are crucial, ratchet binders are the way to go. If you have any trouble in choosing load binder, you could consult Sail Rigging freely. Our product manager will provide whole solutions to you at first time.